Metro Glass Reference Guide

Please click the links to view information on:

Tinted glass

Laminated glass

Low E glass

Reflective glass

Decorative glass

History of glass

The first glass known to stone-age people was obsidian (black volcanic glass) and was used for making weapons and tools. Man-made glass dates back to around 3500BC and has been found in areas such as Eastern Mesopotamia and Egypt. Little is known about these early adventures with glass manufacture.

By the 11th century, glass manufacturing was developing rapidly in Venice, and this became the leading glassmaking centre for the western world. As many Venetians left in pursuit of an improved lifestyle, the glassmaking skills and style they had developed began to spread across the globe. By the late 16th century many English glassmakers had begun to work with the Venetian style/method.

Early window glass was made by blowing glass bottles or large glass disks. The bottles were cut into pieces, flattened together, and then window panes were cut from the large surface. Most glass for windows up to the early 19th century was made from rounds, while during the 19th century it was usually done using the bottle method.

Demand for glass products continued to increase and in the early 20th-century machinery and processes had been developed to mass-produce window glass. Sheet and plate glass production methods offered significant improvements in large-scale production of flat glass, but still relied on extensive grinding and polishing of the glass to improve the optical qualities and surface finish.

What is float glass?

One of the most significant advancements in glass manufacture was the float glass production method, introduced in the mid-1900s by Sir Alastair Pilkington & Kenneth Bickerstaff. Float glass is the most widely used form of glass in the construction industry as the manufacturing method gives the sheet uniform thickness and very flat surfaces, compared to other manufacturing methods which may require extensive grinding and polishing of the glass surfaces to achieve a flat and even product. If you look closely at older buildings, the difference between windows replaced with modern “flat” float glass and the wavier older style glass product can be seen in the reflections.

While each glass plant is different from the other, the float glass production process can be divided into five universal steps:

Batching of raw materials: The main components, namely, soda-lime glass, Silica sand (69 to 74%), Limestone (5 to 14%), Soda ash (10 to 16%), Dolemite (0 to 6%), Alumina (0 to 3%), and others (0 to 5%), are weighed and mixed into batches to which recycled glass (cullet) is added. The use of ‘cullet’ reduces the consumption of natural gas. The materials are tested and stored for later mixing under computerised control.

Melting of raw materials: The batched raw materials pass from a mixing silo to a five-chambered furnace where they become molten at a temperature of approximately 1500°C.

Drawing the molten glass onto the tin bath: The molten glass is “floated” onto a bath of molten tin at a temperature of about 1000°C. It forms a ribbon with a typical working width of 3210mm, which is normally between 3mm and 25mm thick. The glass (which is highly viscous) and the tin (which is very fluid) do not mix and the contact surface between these two materials is perfectly flat.

Cooling of the molten glass: On leaving the bath of molten tin, the glass – now at a temperature of 600°C – has cooled down sufficiently to pass to an annealing chamber called a lehr. The glass is now hard enough to pass over rollers and is annealed, which modifies the internal stresses enabling it to be cut and worked in a predictable way and ensuring flatness of the glass. As both surfaces are fire-finished, they do not require grinding or polishing.

Quality checks, automatic cutting, and storage: After cooling, the glass undergoes rigorous quality checks and is washed. It is then cut into sheets sizes of up to 6000mm x 3210mm which are in turn stacked and stored, ready for transport.

Approximately 90% of flat glass produced worldwide is manufactured by the float glass method.

Metro Performance Glass sources float glass from several reputable international glass manufacturers, including AGC, Guardian & Xinyi.

Glass production in New Zealand

Glass manufacture has a long, although not always successful, history in New Zealand. To begin with, all glass products were imported, but it was not long until emigrating craftsmen began using their skills and overseas experience to open their own glass workshops. Around 1871, it was reported that the rapid success of the Union Street Glass Works in Auckland was causing importers of wine glasses, kerosene lamps, glass jars, etc to look for other kinds of merchandise to bring into the country.

One of the larger New Zealand based glass operations was the McKendrick Glass Manufacturing Company, established in Whangarei in 1962. The sheet glass production facility was sited in Whangarei for a variety of reasons, most significantly the cheap land and finance for buildings provided by the Whangarei Harbour Board. Other factors included the proximity to a source of high-quality silica sand from Parengarenga Harbour (Parengarenga silica sand has been noted as “good” compared with sources in the “UK” – “it has better grain size, fewer contaminants, and a helpfully low iron level”. Pilkington acquired the Whangarei production site a few years later, and partnered with Australian Consolidated Industries Ltd, to form New Zealand Window Glass Ltd.

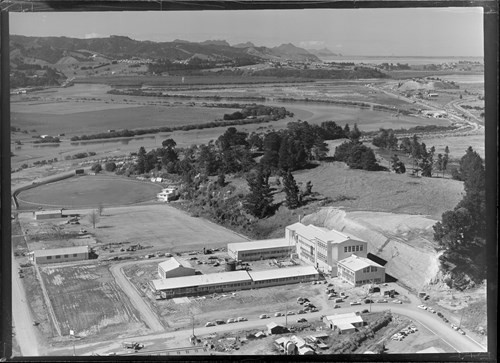

(Glass Works, Whangarei City (source New Zealand National Library)

During peak operation in the plant employed approximately 215 people, had eight salespeople based in Auckland, and produced approximately 850 tonnes of glass per week, of which 30% is lost. This equates to approximately 76,000 square metres – enough to cover 12 rugby fields. Approximately 40% of production was exported to Australia, Japan, and around the Pacific. Regular maintenance ensured the plant and tank operated correctly, but about every 6 years a full rebuild of the glass tank was required. The plant shut down, the tank was emptied and the old bricks which had withstood the 1600oC tank temperature were replaced. After the 4-week shutdown, bringing the tank back up to temperature took around 3 weeks.

Glass production stopped at New Zealand Window Glass in February 1991. The glass tank was slowly cooled down, and approximately two months later the glass was cool enough to be chipped out with pneumatic hammers and sold (typically $1/kg) for “gardens, ornaments, paperweights & mementos”. After 18 years of production, window glass once again needed to be imported to New Zealand.

Ref:

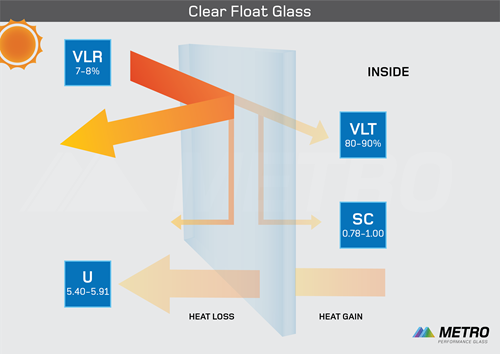

Clear float glass

Clear float glass is the building block for many types of interior, exterior, and architectural glass products. As the name suggests, clear float glass is transparent, offering high visible light transmittance (VLT). Clear float glass is imported in containers and is supplied in packs, cases, and end-caps. Clear float can be processed into heat strengthened, toughened, laminated, and coated glass, and combined to form laminated glass and insulating glass units (IGU).

The visible light transmittance values for clear float glass vary with the product thickness – typically around 90% VLT for 3mm thickness, down to 80% VLT for 19mm thickness.

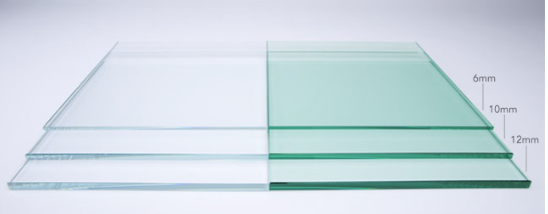

Clear float stocked thicknesses

2mm

3mm

4mm

5mm

6mm

8mm

10mm

12mm

15mm

19mm

For maximum stocked glass sheet sizes visit the following link: Glass Sheet Sizes, or call customer services for availability.

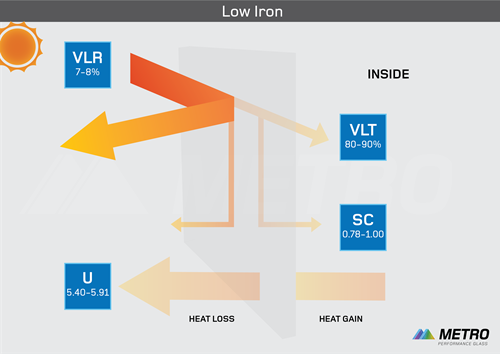

Low iron float glass

Standard clear float glass has an inherent green tinge which is more apparent when viewing the edge of the glass, or in stacks of glass panels. This is due to the iron content in the silicate (sand) and the resulting iron oxide in the molten glass mixture, which helps to lower the required manufacturing temperature. Low iron glasses contain approximately one quarter of the iron content of standard clear float glass, providing a glass that is noticeably clearer in appearance.

Low iron glass is ideal in decorative and furniture applications, showcases, showers, shop fronts, and toughened glass entries. In particular, areas that have white backgrounds (like the white tiles in a shower) benefit from the use of low iron glass to avoid the green tinge often seen with standard float glass.

Low iron glass can be used in almost all locations where regular float glass would be specified, provided solar control is not a significant requirement. Low Iron glass is also ideal for applications requiring colour-backing or painting, due to the high light transmittance and true colour appearance.

The visible light transmittance values for low iron float glass only vary slightly with the product thickness – typically around 90% VLT for all thicknesses.

Low iron float stocked thicknesses

4mm

5mm

6mm

8mm

10mm

12mm

15mm

For more information on stocked glass thickness or maximum sheet sizes, please visit the following link: Glass Sheet Sizes

Tinted float glass

Body tinted (or heat-absorbing) float glass is produced by the same process as clear float glass, however, manufacturers can introduce colouring agents (such as small quantities of metal oxides) during float glass production to tint the glass in a range of shades. The most common colours are grey, bronze, green, and blue. Apart from its function in an aesthetic sense, tinted float glass is also used to reduce solar heat gain, UV radiation, and glare inside a building.

Tinted float glass achieves its performance by absorbing solar energy and so is sometimes referred to as heat-absorbing glass. This heat absorbing quality means the glass is more susceptible to thermal stresses, so some thicker and/or darker products may need to be suitably heat-treated to avoid breakage due to thermal stress.

Tinted float glass has the same versatility as clear float glass and can be processed into heat strengthened and toughened glass, and combined to form laminated glass and Insulating Glass Units (IGU).

For more information please visit our Tinted Glass range.

Tinted glass

What is tinted glass?

Body tinted (or heat-absorbing) float glass is produced by the same process as clear float glass, however, manufacturers can introduce colouring agents (such as small quantities of metal oxides) during float glass production to tint the glass in a range of shades. The most common colours are grey, bronze, green, and blue. Apart from its function in an aesthetic sense, tinted float glass is also used to reduce solar heat gain, UV radiation, and glare inside a building.

Tinted float glass achieves its performance by absorbing solar energy and so is sometimes referred to as heat-absorbing glass. This heat absorbing quality means the glass is more susceptible to thermal stresses, so some thicker and/or darker products may need to be suitably heat-treated to avoid breakage due to thermal stress.

Tinted float glass has the same versatility as clear float glass and can be processed into heat strengthened and toughened glass, and combined to form laminated glass and Insulating Glass Units (IGU).

Tinted float glass colour selection

Tinted float glass samples are available by request from Metro Performance Glass. Due to the significant variance in lighting conditions, it is recommended to view tinted glass samples in light conditions as close to the installation conditions as possible, before selecting a tint colour.

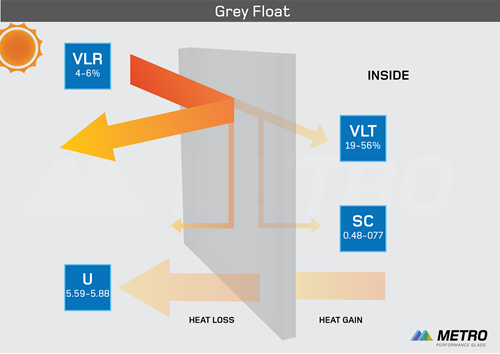

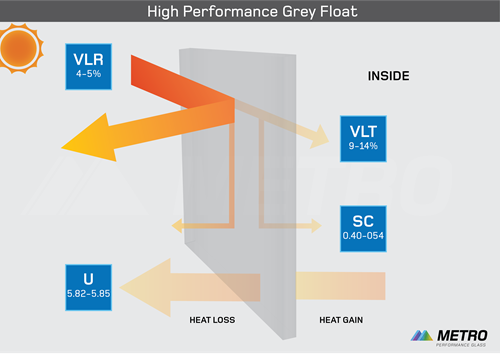

Grey tinted float glass

Grey float is the traditional medium grey tinted glass characterised by its low light transmission and good control of solar heat and glare.

Grey Tinted Float stocked thicknesses

4mm

5mm

6mm

8mm

10mm

12mm

For maximum stocked glass sheet sizes visit the following link: Glass Sheet Sizes, or call customer services for availability.

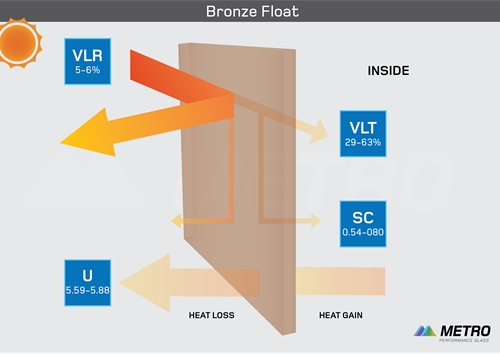

Bronze tinted float glass

Bronze float is the traditional medium bronze-tinted glass designed to reduce solar heat and glare but providing a higher visible light transmittance than grey float.

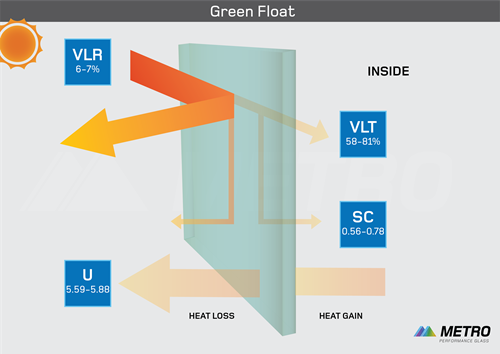

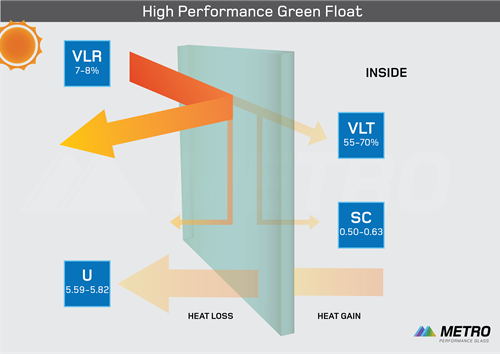

Green tinted float glass

Green float was initially used for automotive applications as it has a very high light transmission. Modern green tints offer better solar performance with superior light transmittance to traditional bronze tints. Green tints can be useful to enhance the appearance of greenery in the surrounding environment.

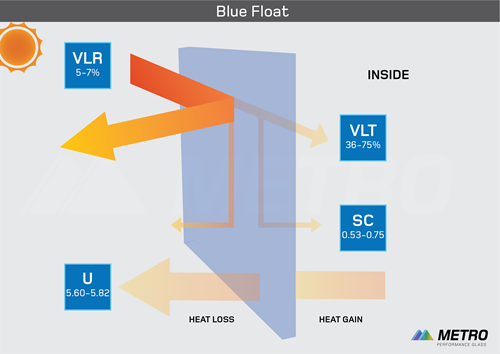

Blue tinted float glass

Dark blue-tinted glass provides an alternative to grey and bronze tint with comparable solar control performance. Light blue tinted glass is ideal if a thicker glass is required with high light transmission.

High performance tinted float

In recent years a number of float glass manufacturers have developed high-performance tinted float products that are engineered to lower the traditional compromise between high light transmission and low solar gain. Other products have been designed for very low light transmission. These products, which are a further development on standard tinted products, also give significant benefits when used in conjunction with Low E glass in Insulating Glass Units. Some of these products may require suitable heat treatment in applications that create high thermal stress in the glass.

*Modern high-performance Low E can provide better solar control performance than tints while allowing more visible light than tinted float glass.

High performance green tinted float

High performance green tinted glass is generally quite dark and combines low solar heat gain, high light transmission performance, and very good UV reduction. Green tints can be useful to enhance the appearance of greenery in the surrounding environment.

High performance grey tinted float

A distinctive dark grey tinted float glass that provides very low light transmission and very good glare and UV control. The tint provides high heat absorption compared to regular tinted glass and provides a lower solar gain.

High performance “special project” tinted float

There are various other types of tinted float glass available by special order. If you require something that is outside any of the groups listed above, please contact Metro Performance Glass and we will investigate placing a special order from our suppliers (lead-time and indent cost TBC for special orders).

Laminated Glass

History of laminated glass

It is widely recorded that laminated glass was invented around 1903 when Edouard Bénédictus was inspired by a laboratory accident. A glass flask was knocked onto the floor but rather than shatter into small pieces as expected, the flask cracked but largely maintained its shape and structure. Upon further investigation Bénédictus found that the glass had at one time contained plastic cellulose nitrate, which had dried on the flask and created a type of adhesive film coating the inside, which kept the glass from shattering in the normal fashion when it was dropped. A few years later various patents for glass/plastic composite panels and layers of glass bonded with balsam were filed – these are widely regarded as the first true laminated glass.

Early laminated glass was slow and challenging to produce, meaning it was also expensive. In the late 1920’s the Polyvinyl Butyral (PVB) plastic interlayer was developed by Canadian chemists Howard W Matheson & Frederick W Skirrow - within 5 years of full production PVB had effectively replaced all laminated glass predecessors.

What is laminated glass?

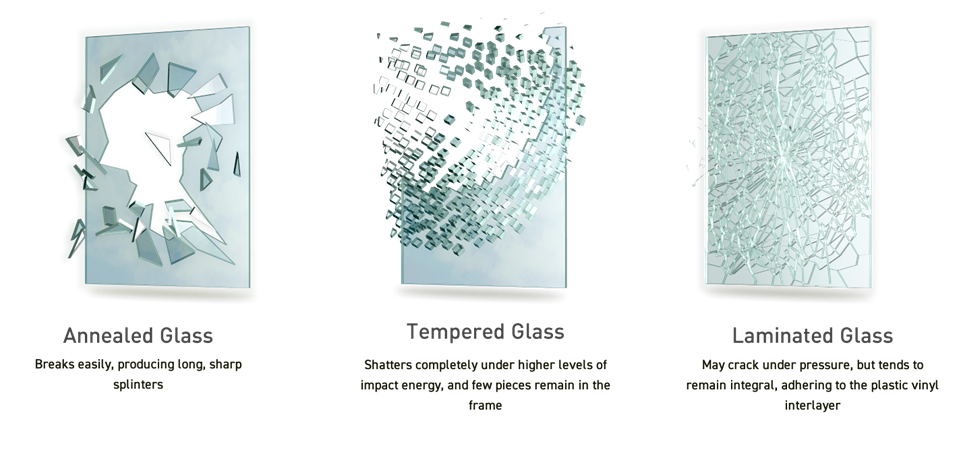

Laminated glass is a form of safety glass in which the glass layers (typically two or three) are held in place by an interlayer product. The interlayer keeps the layers of glass bonded to each other even if the glass is broken, helping the glass maintain its original shape and reducing the likelihood of large sharp pieces detaching. From a “consequence of failure” perspective, this makes laminated glass much safer as it considerably reduces the likelihood of injury to pedestrian traffic from broken glass fragments.

There have been many variations of the processes and products used to form the interlayer. The most common modern interlayers are Polyvinyl Butyral (PVB) and Ethylene Vinyl Acetate (EVA).

Modern laminated glass is produced by bonding two or more layers of glass (annealed, heat-strengthened or toughened) together with a plastic interlayer (usually PVB or EVA). The plastic interlayer is sandwiched between the glass layers, using heat and pressure (typically a vacuum bag and autoclave) to expel any air pockets and bond the layers together.

Applications & benefits of laminated glass

The layered and bonded structure of laminated glass offers several benefits in terms of design flexibility. The layered nature of laminated glass means the layers can be made with different interlayers and different types of glass (including some coated glass types) to tailor the performance of the panel to the installation requirements. This layered construction also means that laminated glass typically blocks more noise and UV light than single glass.

Safety, security & protection

Where ordinary glass (annealed, heat-treated & toughened) will break into fragments and fall apart when broken (with potentially dangerous sharp pieces and fragments), the bond between the glass and interlayer in laminated glass adheres any broken fragments, keeping the glass intact and resisting penetration.

This important breakage characteristic significantly reduces the likelihood of serious injury, qualifying laminated glass as a Grade A safety glass in accordance with AS/NZ 2208 and other international standards.

Compared to ordinary glass, laminated glass offers greater protection for people and property by providing a more effective barrier from attack and un-authorised entry. Although the glass will break if hit hard enough with a hammer, brick or similar object, the interlayer offers additional resistance to penetration, ensuring any attempt to enter a premises will be slower and noisy, increasing the likelihood of the attempted entry being abandoned or detected.

In addition, the attacked glass will tend to remain in the opening, keeping wind and rain out of the building until it can be replaced at a convenient time. The type of laminated glass specified can be matched to the level of security/resistance required.

Laminated glass performance options

Fading / UV Control: The largest contributor to deterioration and fading of interior furnishings is typically UV light coming in through glass windows and doors. Laminated glass interlayers typically have UV-absorbing additives to virtually eliminate the sun’s UV radiation while allowing important visible light to pass through. For additional fading control, glass which absorbs or reflects solar radiation (eg reflective, tinted and/or Low-E glass) can often be included as part of the laminated glass specification.

Sound Reduction: Most exterior noise finds its way inside by taking the path of least resistance, typically through any window glass. Laminated glass is very effective in reducing the transmission of noise through glazing as it has a higher sound reduction index than monolithic glass (of equal thickness), particularly between 125Hz and 4000Hz. The increased sound reduction is due to the vibration dampening effect of the plastic interlayer sandwiched between the plies of glass. Specially formulated soft interlayers have been developed to offer a more pliable and elastic option than traditional PVB interlayer, increasing the sound reduction effect. However, if noise reduction is a key issue, it’s best to engage an acoustics consultant to assess the build or renovation. They will make a recommendation for the key frequencies of the sound at the particular location. They can also review the structural elements for the build to ensure a complete solution. For example, the interaction of glass, joinery and the building envelope are key. For the best sound reduction, thermally broken frames are also recommended.

Laminated glass appearance options

Laminated glass can not only be made with a range of tinted glass, there are also a wide variety of specialist opaque and coloured inserts to achieve a great variety of appearance options.

The majority of interlayers are also compatible with digital print on the glass itself, or can be combined with specialist printed inserts to create a full digital image captured inside the laminated glass panel.

Due to the controlled nature of the laminating process, façades glazed with annealed laminated safety glass reduce the level of visible distortions that are created by the heat treatment processes required for toughened safety glass, providing significantly sharper visual transmission and reflected images. These benefits are however dependent on the nature of the final processed product and it should be noted that annealed laminated glass has a higher thermal safety risk (a detailed check should be undertaken to ensure the selected laminated glass type is suitable for the application).

Considerations when selecting laminated glass

While laminated glass offers many benefits, as with most building products, there are some additional characteristics and considerations when using laminated products (general considerations are listed below – please refer to the separate laminated glass type sections regarding special considerations for different types of laminated glass).

Edge Delamination is one of the most commonly raised concerns when discussing laminated glass products. Edge delamination is possible in all laminated glass products, and is the result of the breakdown of the bond between the glass and the interlayer, usually by atmospheric moisture attack, or degradation resulting from incompatibility with materials in the glazing system, chemicals from atmosphere or from washing solvents etc. Certain conditions will accelerate (or reduce) the extent of edge delamination, but as a rule edge delamination should not extend more than 6mm from the panel edge.

Examples of edge delamination, likely due to prolonged exposure to moisture or chemical attack from incompatible cleaning products.

For all laminated glass types, it is necessary to verify compatibility with glazing materials in contact at the edges - such as but not limited to sealants - in order to assess the risk of delamination and/or discoloration during the panels service life. Compatibility of any cleaning agents/products used must also be confirmed, for the same reasons.

Since the interlayer used in PVB laminated glass is hygroscopic (tends to absorb moisture), delamination is most likely when the glass is installed with an exposed edge. For PVB laminated glass it is recommended that the edges be fully glazed in a well-drained framing system that is designed to reduce the likelihood of condensation and prevent the accumulation of moisture.

While EVA laminated glass is far less susceptible to moisture ingress than PVB, making it better suited for exposed edge applications, EVA laminated glass must not remain in prolonged contact with moisture or be permanently immersed in water otherwise it is subject to the same risks of delamination and/or discoloration.

Reflection & Distortion properties of laminated glass vary depending on its glass components (annealed or heat treated) and also the orientation of each glass component in the make-up. While a certain level of distortion is inherent to laminated glass from its manufacturing processes (even when annealed glass is used) the expected distortion of an annealed laminated safety glass panel is less than an equivalent thickness monolithic toughened safety glass panel. A higher level of distortion is expected with the use of heat treated glass in laminate – the distortion level will be consistent with that expected for monolithic heat treated glass.

Color Matching to a keen and/or trained eye colour differences may be apparent when comparing laminated glass to adjacent monolithic panels. With the range of tinted and low-iron glass, and tinted interlayers options available (by special order), there are multiple ways of achieving different colour effects in laminated glass. There are also many options available by using specialist colour inserts and/or modern digital print technology.

Types of laminated glass

By far the most common types of laminated glass use Polyvinyl Butyral (PVB) or Ethylene Vinyl Acetate (EVA) interlayer materials. PVB and EVA are both thermoplastic polymers (often described as soft polymer materials) with inherent elastic and adhesive properties. While PVB and EVA are both thermoplastic materials, their chemical structures are quite different, resulting in some differing characteristics.

Laminated glass used as safety glass in buildings (or as automotive glazing) must be marked with identification. Refer to the Glazing Compliance – Safety Glass Marking section for further information.

Laminated glass with PVB interlayers

By far the most widely used laminated glass type in the world, PVB interlayers offer optical clarity, flexibility and good adherence to a wide range of surfaces. PVB laminated glass is not manufactured in New Zealand but is brought in (imported) in annealed laminated stock sheet format. These stock sheet sizes are then cut to the required finished shape and edge-worked ready for installation.

The PVB interlayer most commonly used is “clear” type, however PVB is also available (by special order) in a wide range of tints, translucent white, and colours, in various thicknesses. The minimum interlayer thickness is 0.38mm for annealed glass and 0.76mm for heat strengthened and toughened glass (heat strengthened and toughened PVB laminated glass is not stocked and requires a special order to be placed). Standard thickness interlayers are also available in 0.76mm, 1.14mmm or 1.52mm. All interlayer thicknesses pass the Grade A safety glass test, with the thicker options (typically 1.52mm) used in products described as “Intruder Resistant”.

(Close-up shot of a laminated glass panel part of an internal glass balustrade).

Given all readily available PVB laminated glass (in New Zealand) comprises annealed glass, an assessment of thermal breakage risks is advisable for each application. All annealed glass is subject to thermal breakage if the installation as a whole is likely to result in the PVB laminated glass developing excessive temperature differences within its panes. The threshold widely considered to prevent the risk of thermal breakage in annealed glass is a maximum temperature difference of 40 degrees within any pane of glass. The risk of thermal breakage is significantly higher if any pane of the PVB laminated glass comprises tinted and/or coated glass. If there is doubt/concern, a detailed thermal assessment/analysis should be undertaken. For applications subject to the risk of thermal breakage, the alternative of heat-treated laminated glass (heat strengthened laminated glass or toughened laminated glass) should be assessed, along with considerations on costs and inconveniences associated with replacing glass if breakage occurs – a very specific example of this would be the use of PVB laminated glass in a structural glazing application. Please note that thermal breakage is not covered by MPG’s standard warranty.

It is also important to note that PVB interlayer properties are responsive to temperature - for higher temperature applications the weakening of the interlayer should be considered during the design process.

Acoustic Laminated Glass utilises a specifically designed acoustic PVB interlayer to further reduce sound intrusion into buildings. The acoustic grade PVB interlayer is a typically a clear 0.76mm product, with increased elasticity (compared to the standard PVB interlayer). The increased elastic behavior of the acoustic interlayer offers greater damping effect and hence increases the sound reduction effect.

* For information on stocked glass thickness or maximum sheet sizes, please visit the following link: Glass Sheet Sizes

Laminated glass with EVA interlayers

Metro Performance Glass stock the following sizes of Acoustic Laminated PVB glass:

By far the most prominent laminated glass manufactured in New Zealand, EVA laminated glass uses Ethylene Vinyl Acetate (EVA) interlayer that is far more resilient when exposed to moisture and offers improved adhesion to glass and other materials, compared to PVB interlayers.

The EVA laminated glass manufacturing process normally involves a batch oven to create temperature, with pressure created with vacuum bags, and is a low to medium volume process. It is often known as “batch laminating” as the glass panes are laminated together in oven batches. An important difference with EVA is that it is a thermoset product – during the lamination process, the temperature and pressure are applied and the interlayer undergoes a chemical transformation from a “soup of flowing molecules” to a more stable chemically cross-linked EVA molecule.

EVA laminated glass is less susceptible to temperature softening and edge de-lamination due to its higher resistance to moisture – PVB has an average tendency to permeate water 8-9 times higher than EVA. While this makes EVA laminated glass better suited for exposed edge applications, EVA must also not remain in prolonged contact with moisture or be permanently immersed in water otherwise it is subject to risks of delamination and/or discoloration. Also, like PVB, it is necessary to verify compatibility with glazing materials in contact at the edges - such as but not limited to sealants - in order to assess the risk of delamination and/or discoloration during its service life.

As EVA laminated glass can be made in relatively small batches, it is particularly suited to using different glass types to achieve a more specialised finished product. EVA can be used with multiple glass types (annealed, heat-strengthened & toughened) and with some specialized glass such as wired or patterned (provided one glass surface is plain/flat).

EVA is particularly suited for laminating special inserts inside the glass panels, such as PET film, mesh, decorative laminates, and is used extensively (internationally) for laminating glass with photovoltaic solar cells.

Laminated EVA Range

Metro Performance Glass manufactures Laminated EVA panels to the size and specification required for each application. Due to the machinery and components required for this process, there are some size limitations on what can be readily supplied:

Maximum size 4500mm by 2400mm.

Maximum readily available total panel thickness 40mm. Thicker panels are possible, but must be discussed and confirmed as available.

Maximum weight 500kg. Anything above 300kg should be discussed in detail to confirm practicality of handling this weight of panel.

EVA interlayer is stocked in clear 0.38mm and 0.76mm thicknesses, and opaque 0.38mm thickness. The interlayer can be stacked to achieve a greater overall thickness, where required. Other interlayer options are available by special order – please check with your local Metro Performance Glass or Metro Direct office for product options & availability.

* For information on stocked glass thickness or maximum sheet sizes, please visit the following link: Glass Sheet Sizes

Laminated STF (Sentry) - rigid EVA interlayer

An increasingly popular option in New Zealand, Laminated STF (Sentry) uses an EVA interlayer product that is significantly more rigid/stiff than the traditional PVB or EVA interlayer material. Laminated STF (Sentry) glass offers superior performance capabilities, particularly strength and stiffness, and in a range of scenarios can offer advantages over both PVB laminated glass and EVA laminated glass options. Similarly to EVA laminated glass, since the lamination process is undertaken through batch laminating ovens in local manufacturing plants, Laminated STF (Sentry) glass can use both annealed and heat-treated glass (heat strengthened or toughened) and this considerably enhances its structural capability as well as resistance to thermal breakage (should this be a consideration).

STF (Sentry) is a specially formulated “ionoplast” (semi crystalline) polymer interlayer that was developed by DuPont (USA), and is progressively emerging as the interlayer of choice in certain high-performance glazing applications on account of its “stiffness” and excellent weathering capabilities. STF (Sentry) is typically five times stronger and 100 times stiffer than traditional interlayer products. Due to its strength and stiffness, it offers enhanced structural properties which make it ideal for laminating glass for special applications such as structural glass walls, fins, balustrades, floors, and security applications.

A particular advantage of Laminated STF (Sentry) glass is its post breakage behavior, on account of the strength and stiffness of the interlayer. While both PVB and EVA laminated glass are associated with what is commonly referred to as a “blanket effect” when all panes of the laminate have sustained breakage (the glass is held together, but the reduced structural strength isn’t enough to hold the glass in position) Laminated STF (Sentry) glass maintains better structural integrity in such situations. For example, the STF (Sentry) interlayer is sufficiently strong and stiff that it can hold a toughened laminated panel together even if both panes are fractured. For balustrade glass, Laminated STF (Sentry) is able to satisfy the NZBC requirements for post-failure performance (when both glass panels are broken) without the need for an interlinking rail or stiffening brackets**, offering the least interruption of the desired view.

The STF (Sentry) interlayer is available in roll and sheet format in a range of thicknesses, and demands very particular storage and processing controls in order to yield a quality end product. Laminated STF (Sentry) glass is very stable at the edge from moisture attack and resistant to UV discolouration, however, as for other interlayers, care is required to verify compatibility with glazing and cleaning materials in contact at the edges in order to assess the risk of delamination and/or discoloration during its service life.

**Laminated STF (Sentry) post-failure performance is subject to mounting hardware and glass panel dimension requirements – confirm with Metro Performance Glass.

Laminated STF Offer

Metro Performance Glass manufactures Laminated STF panels to the size and specification required for each application. Due to the machinery and components required for this process, there are some size limitations on what can be readily supplied:

Maximum size 5000mm by 2400mm.

Maximum readily available total panel thickness 40mm. Thicker panels are possible but must be discussed and confirmed as available.

Maximum weight 500kg. Anything above 300kg should be discussed in detail to confirm the practicality of handling this weight of the panel.

STF interlayer is stocked in clear 0.76mm and 1.52mm thicknesses, maximum 2500mm width. The interlayer can be stacked to achieve a greater overall thickness, where required. Other interlayer options may be available by special order – please check with your local Metro Performance Glass or Metro Direct office for product options & availability.

* For information on stocked glass thickness or maximum sheet sizes, please visit the following link: Glass Sheet Sizes

Specialised laminated glass

As well as the most common laminated glass types (PVB & EVA) there is a range of more specialised laminated glass options available:

Automotive laminated glass

Automotive Windscreen High Performance (Auto WHP) laminate is specifically designed for use in automotive windscreens. The WHP PVB interlayer has been designed for the specific requirements of automotive glass, particularly accident impact conditions and high light transmission.

The minimum requirement for standard windscreens in cars or buses is 6.76mm WHP Laminated Safety Glass. Auto WHP is typically available in both green and clear options, both 6.76mm thickness, 1380mm by 2140mm sheet size*.

Ordinary laminated glass or architectural 0.76mm laminated glass must not be used for automotive applications.

*Please check with your local Metro Performance Glass or Metro Direct office for current product availability.

Security laminated glass

Damage caused by vandalism can be minimised by the use of laminated glass, which ensures that any broken shards of glass adhere to the interlayer and acts as a deterrent to burglars by slowing them down and attracting attention. While standard 6.38mm PVB laminated glass will provide increased protection compared to monolithic annealed or toughened glass, the multiple layers of glass and interlayer in specialised security laminated glass offer increased levels of penetration resistance. The amount of protection is dependent on the glass and interlayer type and thickness, and can be selected to suit the anticipated severity and duration of possible attacks.

Forced Entry Protection (FEP) glass is designed to resist attack by intruders, burglars or other persons try to gain entry unlawfully, Metro's product in this segment is called:

Intruder Resistant Glass (serious attack resistance)

Intruder Resistant Glass is manufactured to comply with a range of manual attacks defined in AS3555.1 (Building Elements: Testing and Rating for Intruder Resistance, Part 1 – Intruder resistant panels). This standard has levels of attack using a range of common hand tools, power tools, hydraulic tools and a cutting blow torch. The glass is rated in 5 or 10 minute performance categories, based on the time required to achieve a defined opening size in the glass panel.

Intruder Resistant Glass will generally be multi laminates of glass, or a combination of glass and polycarbonate construction. The multiple layers of glass, polycarbonate, and interlayer make penetration through the glass extremely difficult and time-consuming.

Metro Performance glass can design and manufacture Intruder Resistant Glass with a variety of sizes and thickness specifications to suit a wide range of installation requirements. Please contact your local branch/office for assistance.

Note: The maximum size for glass/ polycarbonate laminates can be restricted by the available polycarbonate sheet sizes (typically 2440mm x 1800mm).

Prison Cell Glass: Similar to Forced Entry Protection glass, PSC (Prison and Suicide Cell) glass is a range of thin, lightweight intruder resistant laminated glass products which have been specifically designed for low to medium security applications, where intrusion or the safety of disturbed criminals or patients is of concern. Prison Cell glass is constructed using combinations of annealed, toughened and heat strengthened glass and polycarbonate, with an interlayer between the plies. This configuration provides residual strength, even after one or both of the glass plies have been broken, making it well suited for watch houses, lock-ups, detention centres, and police stations.

Glass can be manufactured to incorporate tinted glass, tinted or obscure interlayers, and reflective coatings or one-way mirror. Some also have a safety film applied.

Metro Performance glass can design and manufacture Prison Cell Glass with a variety of sizes and thickness specifications (typically 12-22mm) to suit a wide range of installation requirements. PSC glasses are typically tested and specified to the attack levels as defined in AS3555.1.

Please contact your local branch/office for assistance.

Note: The maximum size for glass/ polycarbonate laminates can be restricted by the available polycarbonate sheet sizes (typically 2440mm x 1800mm).

Security Glass Framing: It should be noted that the surrounding frame and support structure are of equal importance to the glass panels themselves and must be of strong construction and capable of providing a level of protection similar to that of the forced entry protection glass. It is important that the framing offer a suitable edge cover of the glass (as a general rule it should not be less than the glass thickness or 20mm - whichever is larger), and must retain the glass both during and after the “attack” period.

Shattered laminated glass

The versatility of glass, particularly when combined in laminated form, has led to many interesting products being available. One of these is the shattered glass laminate – a laminated glass panel that contains an intentionally broken layer captured between two intact layers. This is done to achieve a very unique aesthetic but maintain structural integrity - the effect can be particularly striking when combined with edge or backlighting.

Shattered laminated glass is normally supplied as a triple laminate of toughened safety glass, with the centre shattered ply between 5 and 10mm thickness, and outer plys typically 4mm thickness. The thickness of the shattered ply modifies the size of the fragments which are formed – the thicker the shattered ply, the more effective the shatter pattern. The most common configuration for shattered glass laminate is 4mm toughened / EVA interlayer / 6mm toughened (shattered) / EVA Interlayer/4mm toughened.

Shattered laminated glass can also have two different types of shatter patterns – edge origin or centre origin.

Edge origin is where the shatter pattern originates from one of the panel edges and radiates outward from that point. It is achieved by a pointed impact to the edge of the central toughened glass ply.

IMPORTANT – all the glass plies of the triple laminate should be toughened safety glass, as an annealed outer ply may crack when the centre ply is shattered.

Laminating Coated Glass

Reflective and coated glass can be laminated to provide additional performance benefits. By laminating a reflective glass the coating can be protected inside the laminate and the laminate will provide a safety glass panel with improved sound and UV control properties. Typically the coating is on surface 2 inside the laminate. In some cases the solar control properties of the laminate can be enhanced by using a tinted interlayer.

Both pyrolytic and sputter-coated glasses can be laminated. This is normally done by the EVA batch laminating process after coating and will typically increase lead times for supply. Some coatings can be laminated in New Zealand, but others may require a special order to be placed with overseas suppliers.

* For information on stocked glass thickness or maximum sheet sizes, please visit the following link: Glass Sheet Sizes

“Clear Laminated Coated”, performance values to ranges: VLR 9-10%, VLT 65-67%, SC 0.63-0.66, U 4.0-4.1

Other laminated coated glass options (eg tinted) are available by special order/manufacture – please check with your local Metro Performance Glass or Metro Direct office for product options & availability.

Low E Glass

What is Low E glass?

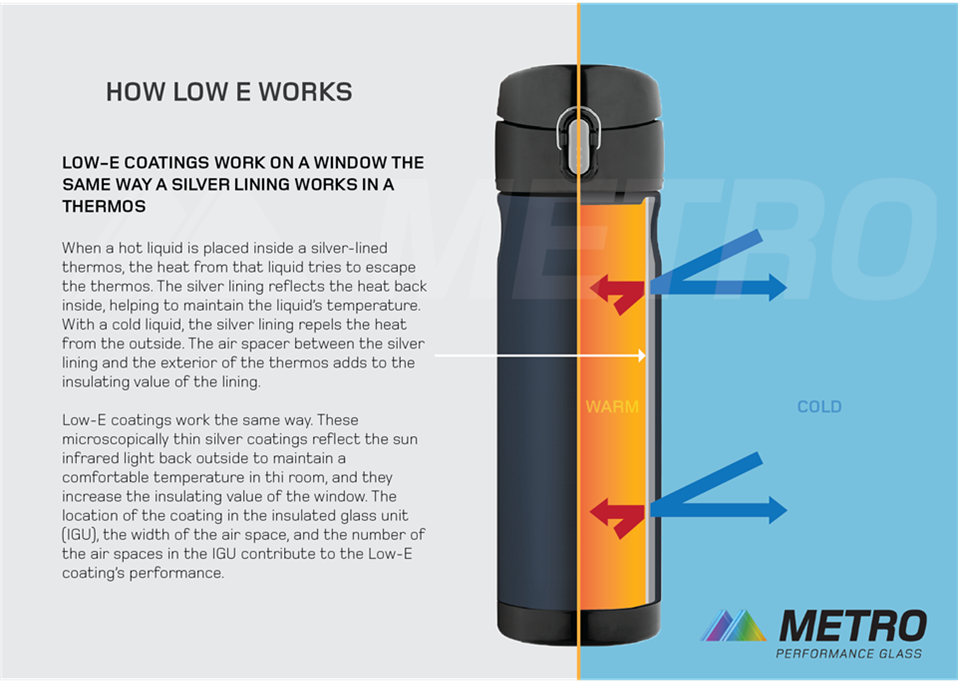

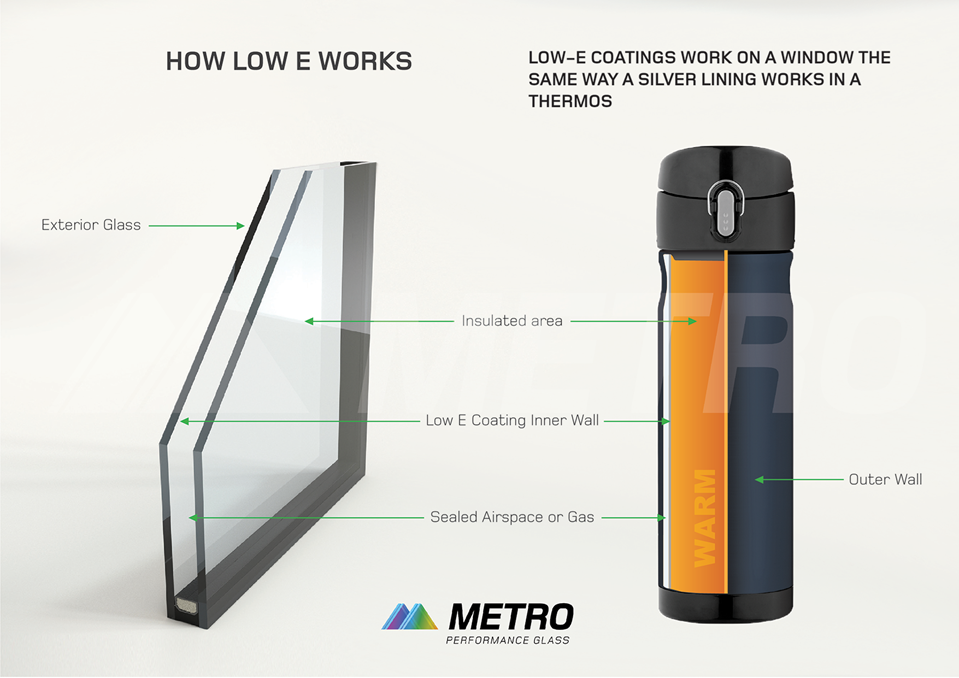

The “E” in Low E is an abbreviation of “Emissivity”, which is a measure of the ability to radiate absorbed energy. Low E glass has a special coating on the glass surface, which reduces the amount of heat transferred through the glass, improving its thermal performance.

Low E coatings are older than you might think. The very first low E coatings were highly reflective silver coatings on "thermos" bottles back in the 1890s. The energy crisis in the 1970s sparked the development of low-emissivity (low-E) coatings for windows. Pilkington and German firm Flachglas Group created the first commercially viable low-E coatings using thin layers of gold. These coatings produced a green hue, leading German glass manufacturer Interpane to develop the first effectively colorless low-E coating using silver layers in 1981.

Today’s low-E coatings contain one or more silver layers that reflect the sun’s ultraviolet and infrared light to help maintain a comfortable interior temperature while allowing for visible light transmission. In the winter, when a building’s conditioned interior is warmer than the outside, the coating works in reverse, reflecting the heat back inside.

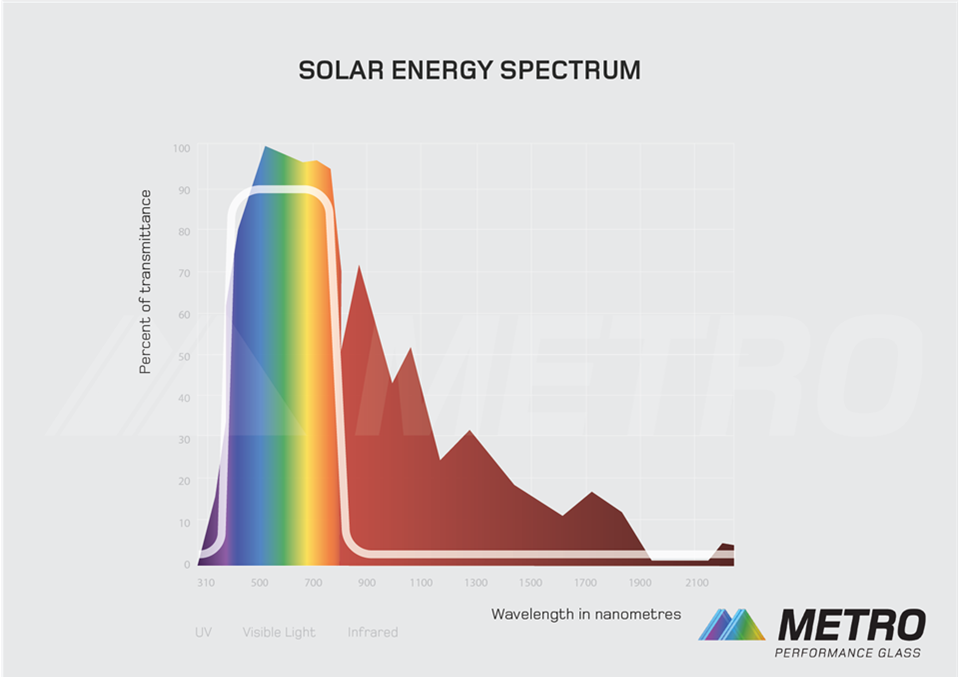

To understand the performance of Low E Glass, it helps to have an understanding of the solar energy spectrum. As you can see in the two graphic below, ultraviolet light (UV), visible light, and infrared light all occupy different parts of the solar spectrum. In the chart you can see how they are delineated according to their wavelengths.

UV light, which contributes to the fading of interior materials such as fgabrics and wall coverings, has wavelengths between 300 to 380 nanometers.

Visible light occupies the part of the spectrum between infrared and UV light wavelengths, measuring from about 380 to 780 nanometers.

Infrared light (heat energy), which is transmitted as heat into a building, begins at wavelengths of approximately 780 nanometers.

Low E coatings have been developed to minimize the amount of ultraviolet and infrared light that can pass through glass without compromising the amount of visible light that is transmitted.

Types of Low E Glass

The Low E coatings are applied either in the Sputter Coating process, also known as Magnetron Sputter Vacuum Deposition (MSVD), which is applied to pre-cut glass in a room-temperature vacuum chamber, or the Pyrolytic coating process, which applies the Low E coating to Float Glass as it is being produced on the float line. While the Pyrolytic process is a newer method for the application of Low E coatings, continued development of the sputter coating process has meant that the vast majority of commercially available Low E coated glass used in IGU’s is applied using the sputtering process. These advancements in coating technology have created more resilient “post temperable” sputter-coated glasses, which means they can be tempered (toughened) after they have been coated. As the coatings are designed to reflect heat they can be difficult to toughen, so with the advent of these new coatings, it has also required glass processors to continue to upgrade their toughening lines to accommodate the processing of these new generation Low E coated glasses.

What this has meant is an explosion of Low E options that can be tailored to meet various building requirements across the world. The options will vary from tuning for reducing heat loss in cold climates to solar control to stop buildings overheating in warmer climates. Some climates require both performance attributes, for example, Central Otago, which has some of the coldest temperatures in New Zealand in the winter, is also one of the areas in New Zealand that gets the most sunshine hours.

Low E coatings can also be coloured, reflective, and or applied to Tinted Float glass to further enhance the performance and or the look of a building.

Any coating applied to the surface of the glass will have some effect on the overall clarity and this has been an important consideration in the development of modern Low E products – obtaining maximum performance with minimal optical impact.

How does Low E glass work?

With advances in technology, sputter coating applies microscopically thin chemical layers in an organised stack. Within these layers are microscopic layers of silver and dielectric (ceramic) materials, which contribute significantly to the performance properties of the coating. This also allows the stacks to be layered for specific performance targeting specific parts of the solar energy spectrum, while also allowing the visible light parts of the spectrum to pass through.

Low E performance considerations

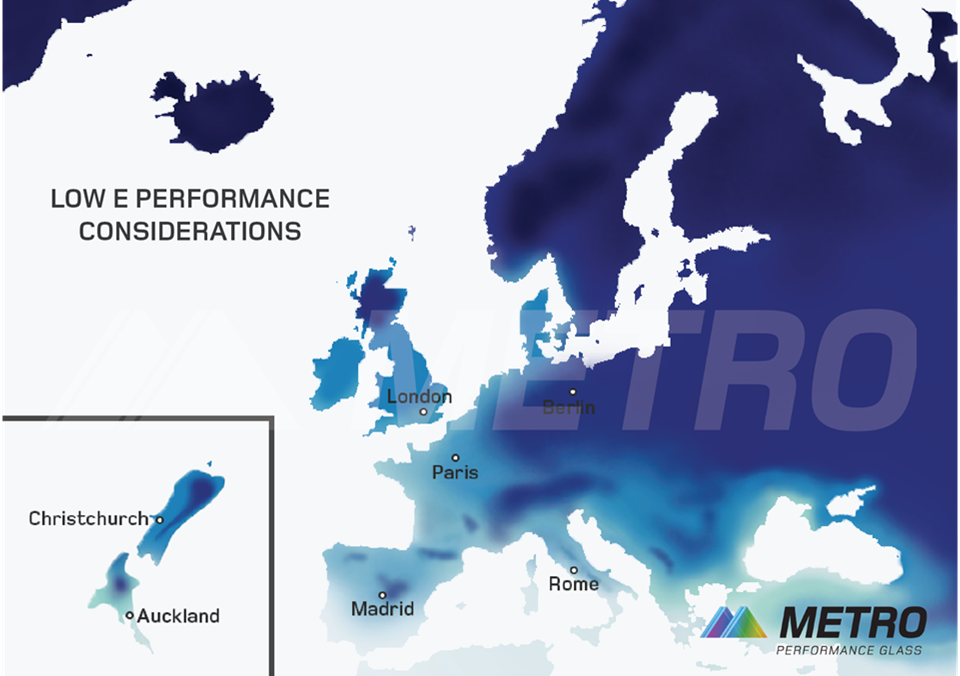

For New Zealand, typical geography is “subtropical in the North to cool and temperate in the South” (NIWA). As an indicative comparison, the map below illustrates where New Zealand would sit next to Europe, at the same latitude (similar to the wine belt, Bordeaux to southern Spain, grapes grow from the very South all the way to the to the North of New Zealand).

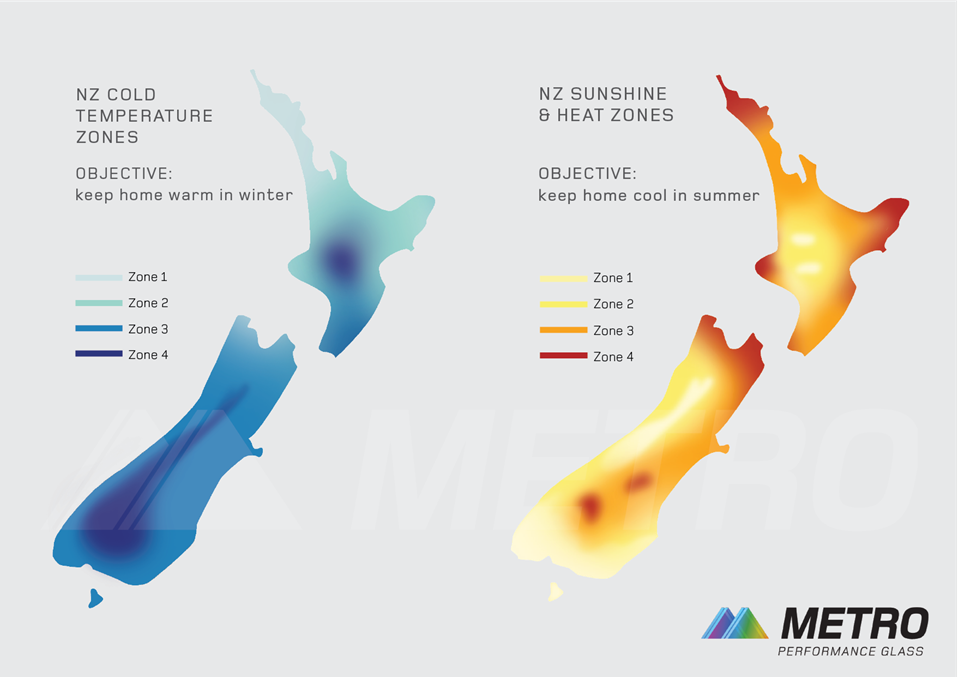

Within New Zealand there are 3 zones set out in the building code for insulation performance, however, Metro and the New Zealand Green Building Council (NZGBC) recognize the Central Otago area as a fourth zone for insulation, with temperatures dropping to -10oC in the winter. Metro has also mapped the areas that receive the highest sunshine hours as a proxy for the need to have solar control.

This means that, while parts of Australia receive much more solar radiation than New Zealand, UV levels in New Zealand are still higher than in Europe and parts of North America. Our most populated centres correspond to latitudes equivalent to the Mediterranean or California. Overall, New Zealand is sunnier than most of Europe and North America, and its peak UV is higher due to the lack of pollution and closer approach to the sun during summer than in the northern hemisphere. Thus it is important when considering the likes of Passive House insulation performance levels, that the potential for overheating is also considered, which in most cases means an all-round performance Low E double glazing unit that has solar control and 0.9U value type performance.

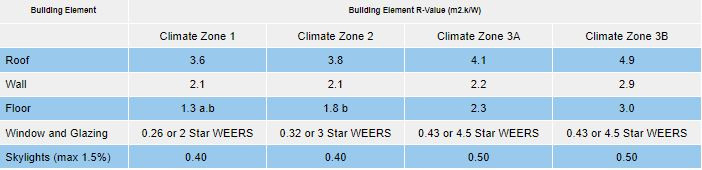

The New Zealand Building Code (NZBC) Energy Efficiency Acceptable Solution H1/AS1 requires compliance with NZS 4218 – Thermal Insulation - Housing and Small Buildings. The tables require a minimum R value of 0.26 and this will normally require IGUs to be used. The building code has not kept up with what is now considered a minimum standard for livable homes. The New Zealand Green Building Council (NZGBC) Homestar 6 level is considered the minimum performance level for social housing.

Both insulation performance and solar control become more important as the amount of glazed area in a building or home increases.

Low E from Metro

When selecting more specialised glass products such as Low E, it is important to be sure of what you are actually getting. Not all glass is created equally and there can be significant variation in optical clarity – this is not always at the front of a customer’s mind, as many assume that glass clarity is always the same.

Metro Performance Glass can supply a significant range of Low E glass products, selected to suit the specific performance and budget requirements of your particular project. No matter where your project falls within the available range, from more budget-conscious first and volume home builders to high-end architectural designs seeking ultimate performance, Metro Low E glass products have been selected to offer the clearest possible option within each market sector.

Low E single glazing

While Low E single glazing was used for a period of time, it has been largely superseded by IGU’s. As the Low E coating in single glazing cannot be sealed off from the atmosphere it is at an increased risk of diminished performance over time, particularly in high humidity areas. Single glazed Low E glass does not provide the thermal performance or comfort and condensation control provided by an IGU, and is not recommended in cold climates or high humidity areas. Thus Low E IGU’s, principally double glazing units, with the ability to seal the coated side of the glass within the unit, have become the preferred solution.

Low E insulated glass units (IGU's)

Insulated Glass Units (IGU’s) are typically double glazing, occasionally triple glazing, and in more extreme cold climates such as Siberia (-45deg temperatures) quadruple glazing is also used.

The beauty of an IGU is the ability to have different glass types in each pane, to allow more options for achieving desired performance and appearance outcomes.

Initially, Low E coatings were placed on surface 2 or 3 (the inside of the IGU). This was done due to the delicate nature of the original soft coatings so that the coating was protected from potential damage. The Low E coatings were typically used on the clear glass on surface 3 of an IGU to improve the thermal heat loss performance (U-Value). Some were applied to the tinted glass on surface 2 of an IGU and used in hotter climates to reduce heat gain (lowering the shading coefficient).

When included in an IGU, generally the Low E Coated glass is on surface 2 of the double glazing unit, with a Warm Edge 3 spacer and gas fill, all factory sealed ready for site installation.

The latest iterations of high-performance Low E double glazing (Low E Xtreme) have a U value (Insulation performance) of 0.9, similar to typical standard Low E triple-glazed IGU’s used in New Zealand in recent years.

Metro generally recommends Low E on surface 2 for New Zealand conditions, however for specific applications please consult with the technical team technical@metroglass.co.nz, as continuing Low E development is shifting the previous givens in IGU design.

Low E in residential insulated glass units (IGU's)

The glass you choose can make a huge difference to the comfort of a house and the size of its energy bills. Because windows are a key design factor for the insulation of houses, Metro Performance Glass offers a range of window glass with high-tech coatings that can be specified to assist in creating the optimum internal environment.

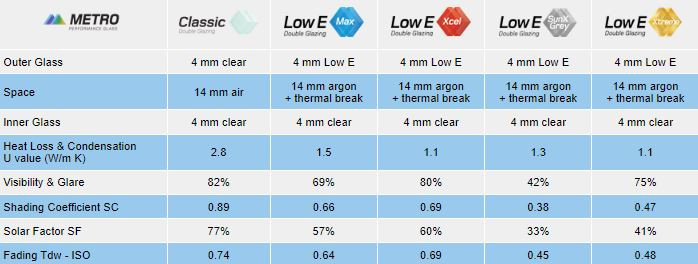

The following overview table details the performance attributes of the Residential range with a 12mm spacer.

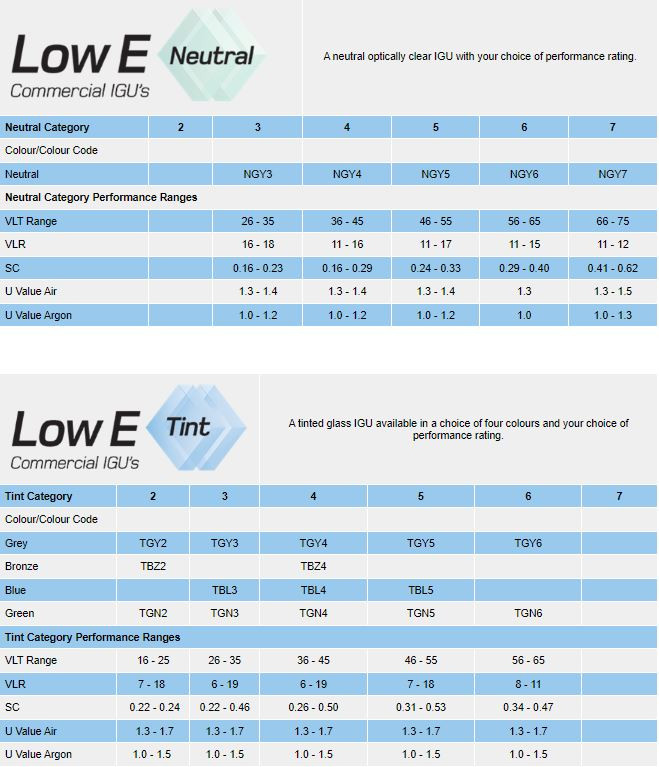

Low E commercial insulated glass units

Creating a high-performance building envelope can be a challenge – finding the balance between capturing and reflecting solar heat, creating a light work environment, and balancing the running costs of HVAC systems. The Metro Performance Glass “Low E Commercial” range provides a simplified construct for commercial building glass selection. (Specific information on Metro's Low E Commercial offer)

The construct columns separate bands of visible light transmission into groups, from there it lays out what performance characters are possible within that band for the many Low E glass types that Metro Glass has access to. Thus the tool allows selection to view the tradeoffs between letting in more light versus light reflectance and or shading co-efficient. The range of insulated glazing units is comprised of three separate groupings – Neutrals, Tints & Reflectives. Simply choose your general building look, then flow through to colour, visible light transmission (VLT), shading co-efficient, and U values.

From this simple selection process the team at Metro Performance Glass can help you further refine your requirements, whether they be noise reduction, wind loadings, printed and/or coloured spandrel panels, or a solar reducing screen print.

Reflective Glass

Reflective and coated glass

The ability to apply surface coatings to large areas of glass (typically 3m by 6m) was essentially driven by the increased construction of buildings with large-area glazing in their design, primarily in the late 1940s. These effectively created greenhouses, which required a large amount of air-conditioning (and hence running costs) to maintain a comfortable internal temperature. Once it was understood and recognized that special coatings could be applied to a float glass surface to make it reflective to short wave radiation from the sun and/or longwave radiation from heat inside or outside the building, the demand developed for coated glass types as an alternative to using coloured glass to reduce the transmittance of solar radiation (coloured glass was comparatively expensive).

Initially, large-scale application of thin coatings to glass, and the subsequent modifications to handling and processing requirements took some time (often decades) to fully develop. Modern glass coatings are more user friendly, and largely completed using two processes – the Sputter Coating process, also known as Magnetron Sputter Vacuum Deposition (MSVD), which is applied to pre-cut glass in a room-temperature vacuum chamber, or the Pyrolytic coating process, which applies the coating to Float Glass as it is being produced on the float line. While the Pyrolytic process is a newer method for the application of glass coatings, continued development of the sputter coating process has meant that the vast majority of commercially available coated glass used is applied using the sputter process.

Pyrolytic Coatings are a metal oxide layer applied on line during the float manufacturing process. The coating is fused into the glass surface at high temperature making it extremely hard and durable. Since the coating is durable it can be glazed to the outside (surface 1) or inside (surface 2) of the building – surface 2 is still the recommended surface for long-term durability. It can be handled and cut like standard float glass and processed into heat strengthened, toughened, laminated, curved glass and Insulating Glass Units. These products are also known as an ‘on line’ or ‘hard coat’ reflective glass.

Sputter Coatings utilise a high technology process in which metal particles are deposited on the glass surface in a vacuum chamber. Almost any non-magnetic alloy can be sputtered, the more common being stainless steel, silver, and titanium. Performance characteristics and colour depend on the alloy and coating density, but in general, they have better solar control performance than pyrolytic coated glass.

Sputter coatings are often called soft coats as the coating is more susceptible to damage than pyrolytic reflective glass when single glazed. Special care is required in cutting, handling, glazing, and cleaning. They are also known as vacuum-coated off-line coatings. These coatings are applied to monolithic.

Advancements in Sputter Coating technology have created more resilient “post temperable” coated glasses, which means they can be tempered (toughened) after they have been coated. As the coatings are designed to deflect heat they can be difficult to toughen, so with the advent of these new coatings, it has also required glass processors to continue to upgrade their toughening lines to accommodate the processing of these new generation coated glasses.

Designing with coated glass offers a great variety of performance and appearance options, and the building designer should consider several aspects when investigating reflective and coated glass for projects:

The aesthetics of reflective glass in relation to the coating reflectivity and orientation of the building. Reflective products can offer the designer a multitude of colour options to enhance or transform a building’s appearance.

The performance of the glass reduces heat gain and cooling costs. Reflective glasses offer superior heat gain performance over tinted glass but this is at the expense of reduced natural daylight levels in a building. In general, reflective glass offers lower UV and visible light transmittance than tinted glass.

The ability of the glass to reduce heat loss and heating costs. This can be improved by using Low E coatings or Insulating Glass Units, or both.

Most reflective glasses absorb and reflect a greater amount of heat than normal tinted float and therefore are more prone to thermal breakage. Toughening or heat strengthening will prevent thermal breakage.

Toughening and heat strengthening of reflective glass will create some roller wave or visual distortion, which can be more apparent on reflective and coated glass (compared to non-coated glass).

Tinted float glass with sputtered coatings is normally heat strengthened or toughened.

Spandrel panels are normally heat strengthened or toughened.

Edges of all annealed coated glass must be good quality clean cut with minimal defects when the glass is being glazed. Sometimes flat ground edges on all sides are specified. Under no circumstances should reflective glass be glazed with damaged edges.

Some Building Consent Authorities (councils) set limits on excessive glass reflectivity (typically around 20%). Most monolithic products should therefore be glazed with the reflective surface to the inside (or surface #2). This will only marginally decrease performance but will enhance the colour of the glass and avoid the strong ‘mirror-like’ appearance when viewed from the outside.

The protection of the coating from damage during construction or cleaning can be an important consideration – refer to the notes below regarding care of coated glass. Under no circumstances can abrasive cleaners be used on any coated surface.

Care of coated glass

Even though coated glass technology has advanced and modern glass coatings are generally far more durable than earlier options, they do still require specific care and handling to minimise the risk of damage and maximize the performance of the coated glass.

When handling coated glass, always use clean, oil-free vacuum pads or gloves.

Coated glass delivery and storage

Make sure the coated glass is always supported.

Protect the coated glass from knocks, abrasions, and excessive pressure – especially on edges.

Keep coated glass surfaces dry, clean, and interleaved with paper or similar approved products.

Do not mark or label the coated surface.

Do not bend the coated glass.

Do not store coated glass in direct sunlight or damp unventilated places.

Glazing coated glass

Take care not to damage the coating when fitting into the frame, or with glazing tools, sealant guns, etc, or by leaning materials against the coated surface.

Glaze with coated surface as specified to the INSIDE or OUTSIDE.

IMPORTANT NOTE – many coated glass types require “edge deletion” or removal of the glass coating in the area’s which will be used for bonding (eg spacer and edge-seal bonding in IGU units, structural bonding to frame/building, edge banding applications, etc).

Remove excess glazing lubricants immediately and check regularly for reappearance.

Clean off splashes from plaster, mortar, or concrete before they harden.

Do not glaze sheets with damaged edges.

Do not use glass with shelled or severely damaged edges.

Do not glaze with coating exposed to weather unless checked and confirmed that this is the correct design.

Do not glaze with putty, acid cure silicone, or other incompatible sealants.

Do not apply solar films to any coated surface.

Do not mark or label the coated surface.

Cleaning coated glass

Always clean coated glass panels as soon as possible after installation, especially if there is a risk of leaching, run-off or spattering from other materials.

Only use proprietary cleaners or well diluted mild detergent for routine cleaning.

Never use abrasive cleaners on or near coated glass.

Coated glass from Metro

Metro Performance Glass stocks a wide range (size and type) of coated glass to suit the most common applications in New Zealand. If you require something that is outside any of the groups listed below, please contact Metro Performance Glass and we will investigate placing a special order from our suppliers (lead-time and indent costs TBC for special orders).

* For information on stocked glass thickness or maximum sheet sizes, please visit the following link: Glass Sheet Sizes

Coated tinted glass

Tinted reflective glass allows multiple options for light filtration and color neutrality, so it’s appearance can be coordinated with a building’s framing, including spandrels, metal panels and even stonework. Reflective glass lets optimal light into your space, but also reduces glare from the sun, which can reduce the need for blinds and other window coverings.

Metro Performance Glass stock the following sizes of “classic” tinted coated glass:

For information on stocked glass thickness or maximum sheet sizes, please visit the following link: Glass Sheet Sizes

Other thicknesses & sizes available by special order – please contact Metro Performance Glass for availability.

*Classic Tinted Coated: performance values to ranges: VLR 10-34%, VLT 19-24%, SC 0.42-0.57, U 5.78-5.80

Metro Performance Glass stock the following sizes of “Supersilver” tinted coated glass:

For information on stocked glass thickness or maximum sheet sizes, please visit the following link: Glass Sheet Sizes

Other thicknesses & sizes available by special order – please contact Metro Performance Glass for availability.

*Supersilver Tinted Coated: performance values to ranges: VLR 10-34%, VLT 29-51%, SC 0.49-0.60, U 5.62-5.81

Reflective Low E glass

For more details, please refer to the separate section on Low E glass products, or contact your local Metro Performance Glass or Metro Direct office.

Mirrored glass

The first mirrors used by humans were most likely reflections in pools of dark still water or water collected in a simple vessel /bowl. As human fascination with reflections grew, understanding developed of the requirements for making a good mirror - a surface with a very high degree of flatness (preferably but not necessarily with high reflectivity as well), and surface roughness less than the light wavelength. Examples of early mirrors (polished pieces of stone, such as obsidian) have been found around the modern-day Turkey region and dated back to 6000BC (polished stone mirrors have also been found in Mesopotamia from 4000BC, and Central & South America from 2000BC).

Production of more sophisticated mirrors made of copper, bronze, silver, gold, and even lead developed later, however, because of the weight of the material these mirrors were quite small (by modern standards) - early metal mirrors rarely measured more than 200mm in diameter. These early metal mirrors were often embellished/surrounded with ornamentation and were primarily used for decoration/ornamental purposes.

Contemporary mirrors did not come into being until the late Middle Ages, and even then their manufacture was difficult and expensive. One of the production problems was that the sand used for the glassmaking often contained too many impurities to produce real clarity. In addition, the shock caused by the heat of adding molten metal for backing more often than not broke the glass.

Modern mirrors are typically made by silvering - spraying a thin layer of silver or aluminium onto the back of a sheet of glass. Justus Von Leibig invented the process in 1835. His wet deposition process involved the application of a thin layer of metallic silver onto glass through the chemical reduction of silver nitrate. The development of this process enabled mirrors to be manufactured on a much larger scale, and for the first time in history, ordinary people could afford to buy a mirror.

Most mirrors today are made by heating aluminium in a vacuum, which then bonds to the cooler glass.

Mirrors are now used for all kinds of purposes, from LCD projection to lasers and car headlights, optical and scientific apparatus such as telescopes, lasers, cameras, periscopes, and industrial machinery.

https://science.howstuffworks.com/innovation/everyday-innovations/mirror1.htm

https://en.wikipedia.org/wiki/Mirror

* For information on stocked glass thickness or maximum sheet sizes, please visit the following link: Glass Sheet Sizes

At this time Metro does not offer a toughened safety glass mirror product, and it is important to note that a toughened safety glass mirror will normally show distortion in reflected images due to the glass toughening process.

Please check with your local Metro Performance Glass or Metro Direct office for any special orders, product availability, and delivery lead times.

Safety mirrors

The term safety mirror is generally used to describe round convex mirrors typically used for viewing at tight corners/intersections where the range of straight-line vision is restricted.

In the context of this document, safety mirror is used to describe flat mirror glass products with a vinyl backing. Vinyl-backed safety mirrors offered increased protection (compared to a conventional annealed glass mirror) in the event of accidental breakage. Where an annealed glass mirror will typically separate into large sharp pieces, vinyl-backed safety mirror fragments should not fall out/down and will be less likely to be penetrated, reducing the likelihood of serious injury. Vinyl backing is available in two options – standard or woven. The woven vinyl backing offers increased strength and tear resistance compared to the standard flat sheet vinyl backing.

Vinyl-backed safety mirror complies with NZS 4223 and AS/NZS 2208 as a safety glass, and can be supplied cut to size, drilled, and edge-worked.

It is important to note that there are special requirements for installing vinyl-backed safety mirrors – detailed information is currently being developed – please contact your local Metro Performance Glass or Metro Direct branch for assistance.

* For information on stocked glass thickness or maximum sheet sizes, please visit the following link: Glass Sheet Sizes

Please check with your local Metro Performance Glass or Metro Direct office for any special orders, product availability, and delivery lead times.

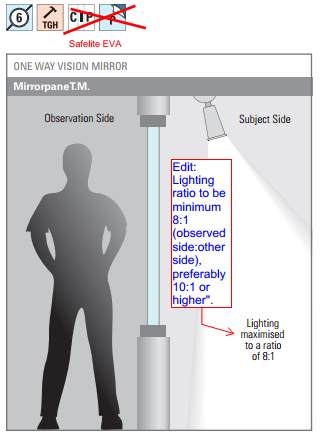

One way vision mirrors

A one-way mirror is a special type of mirror that appears reflective on one side (like a normal mirror) while allowing vision through from the other side. This is achieved by applying the reflective silvering layer but not applying the opaque coating, allowing for very slight transparency through the silvering coating. The perception of one-way transmission is enhanced when the reflective side of the mirror is brightly lit and the other (viewing) side is comparatively dark. This allows viewing from the darkened side but not from the more brightly lit side.

The difference in lighting levels required to achieve the one-way vision effect can be reduced by altering the silvering layer and glass types used. Typically standard one-way mirror manufactured with clear glass requires a minimum lighting ratio of 17:1. Using a more targeted one-way mirror type, the minimum lighting ratio can be reduced to 8:1. It is important to note that when lighting is installed to maximise one-way mirror observation, the lighting source must not shine directly on the mirror, as this will reduce the effect intended.

While some one-way mirror products can be toughened, caution is recommended when specifying this requirement as the toughening process is likely to create some optical distortion in the finished mirror.

As with standard mirror types, one-way mirror is not recommended for exterior installation.

Decorative Glass

Decorative glass

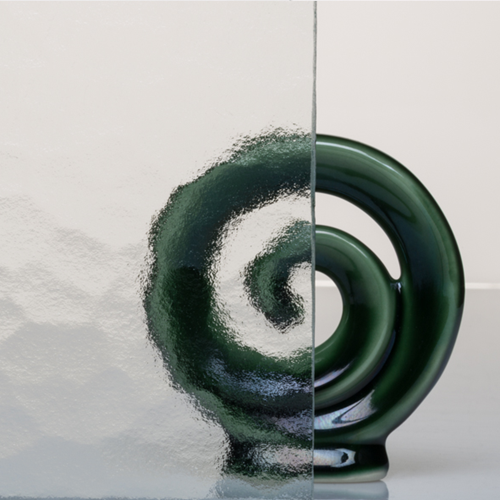

Decorative glass is a term that can be used to describe an extensive range of glass products. In general, decorative glass is used when the glass is intended to be looked at rather than just looked through, or when the glass is used to create a distinct design feature within a space. Decorative glass can be used to add light and create a feeling of space, to introduce more artistic and expressive details, or to increase privacy.

From virtually the first use of glass as a building product, the potential for glass to be used to create features and decorations was recognized - stained glass windows are recorded in use back as far as the 7th century.

Decorative glass can take many forms, and advances in technology and glass production techniques mean there is virtually no limit on the potential for designers to use decorative glass to create artistic and design features in both interior and exterior applications.

In broad terms, decorative glass can be separated into five main groups/categories:

Mirrored glass

Printed & cladding glass

Patterned & wired glass

Specialty glass

Printed & cladding glass

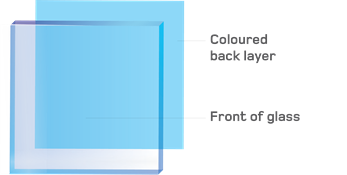

While most people immediately think of windows when glass use in buildings is mentioned, it can also be used (extensively) to create a wide range of finished appearances. Glass cladding panels can be used as a practical, easily maintained, cost-effective alternative to painting, tiling and other forms of “decoration” for both interior and exterior surfaces. Initially used in single colour format, advancements in screen printing and modern digital printing techniques now mean that virtually any image can be created on glass panels.

This decorative process allows the designer flexibility in selecting cladding materials where colour and pattern design are important for visual impact. It also offers creative solutions for controlling solar heat gain, glare and providing privacy.

Typical options for colour coating glass include single coloured (full panel, part panel or edge-banded), screen printed pattern/shapes, grip pattern, or digital print.

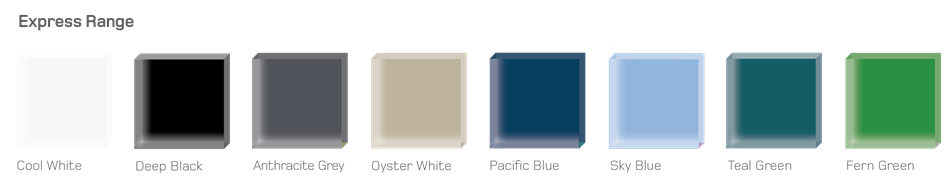

Ceramic frit colours

The ceramic frit/ink used to produce colour coated glass can be selected from a standard range of Architectural Palette colours, Designer Palette colours, or a custom colour created by utilizing the latest colour matching technology.

Colour matching is highly subjective and care should be taken to ensure satisfactory appearance of colour coated glass in-situ, as different light conditions, glass types or installation methods may affect the final appearance.

Architectural palette

The Architectural Palette range contains the most common architectural used to harmonise colour coated panels with tinted vision panels, or conversely to provide a contrasting finish. This range can also be used as decorative colour on patterned panels or slip-resistant floor surfaces.

*The colours shown are an indicative representation only – it is highly recommended to view a physical sample (glass samples are available on request).

Designer palette

The Designer Palette range of colours combines the functionality of glass with a range of bold and vibrant colours. Coloured frit coatings can be used on clear or tinted glass for a variety of internal or external applications. This range can also be used as decorative colour on patterned panels or slip-resistant floor surfaces.

*The colours shown are an indicative representation only – it is highly recommended to view a physical sample (glass samples are available on request).

Colour matching

When the right colour is important and the standard colour palette options aren’t achieving the desired effect, we can colour match to specific requirements.

Typically the colour matching process involves a customer providing a colour identification number or colour sample for matching. A colour-matched glass sample is then prepared and submitted to the customer for approval before manufacture (there can be several iterations of this matching loop to achieve the more difficult colour-match requirements).

Colour identification numbers are recognised from the following colour systems:

Dulux Master Palette.

AS 2700.

BS 4800.

Pantone Matching System.

When colour matching to such a high level, care should be taken to ensure satisfactory appearance of ceramic frit glass in-situ, as different light conditions or installation methods may affect final appearance.

Screen printing

There are various terms used for what is essentially the same technique for transferring ink to a substrate. Traditionally, the process was called screen printing or silkscreen printing (because silk was used to create the “screens”), and it is also known as serigraphy and serigraph printing.

Screen printing first appeared in a recognizable form in China during the Song Dynasty (960–1279 AD) and was subsequently introduced to Western Europe sometime in the late 18th century. Screen printing did not gain large acceptance or use in Europe until silk mesh was more widely available for and a profitable outlet for the finished products was established.

https://en.wikipedia.org/wiki/Screen_printing

Currently, synthetic threads are commonly used in the screen printing process – polyester is the most popular mesh in general use. There are also special-use mesh materials of nylon and stainless steel, and along with different mesh sizes, these can be used to determine the final look of the finished design on the material (eg smaller aperture mesh would be utilized for a design that requires a higher and more delicate degree of detail).

Metro Glass manufacture screen-printed ceramic frit glasses for architectural and commercial use, screen printing ceramic frit paint onto the glass and fusing it onto the surface during the toughening or heat-strengthening process. The result is a tough decorative glass.

Colour coated glass

Metro Performance Glass can supply toughened or heat strengthened glass that has one side coated with permanently fused ceramic frit paint (typically applied by screen printing). The standard colour coat offer is a two-coat process, to increase the finish uniformity and decrease the visibility/likelihood of any defects (particularly when compared to a single coat process/offer). Colour coated glass is normally supplied as toughened safety glass, but can also be heat-strengthened glass or custom laminated glass (using toughened or heat-strengthened plies). The ceramic frit coating can be applied to clear, extra clear, and tinted float glasses in thicknesses from 4mm to 19mm. The coating can be a total coverage coating, a partial coating, or in the form of edge banding.

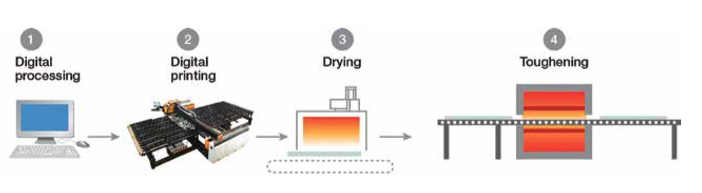

Edgebanding is the common term for the provision of a ceramic frit border (usually black) which obscures visible light and solar radiation from transmitting through the border area. Edgebanding is most common in the automotive and marine industries and is also used in some building glass installations to hide perimeter details (eg IGU units, glass floors, rooflights). Please note that most glass surface coatings require edge deletion (removal of the coating) before the edgebanding is applied.