SafeLite™ STF (Sentry) - toughened laminated glass

SafeLite™ STF Sentry is a toughened laminated safety glass where the glass layers (typically two or three) are held in place by a special high strength interlayer called SentryGlas™ which is five times stronger and up to 100 times stiffer than conventional laminating materials.

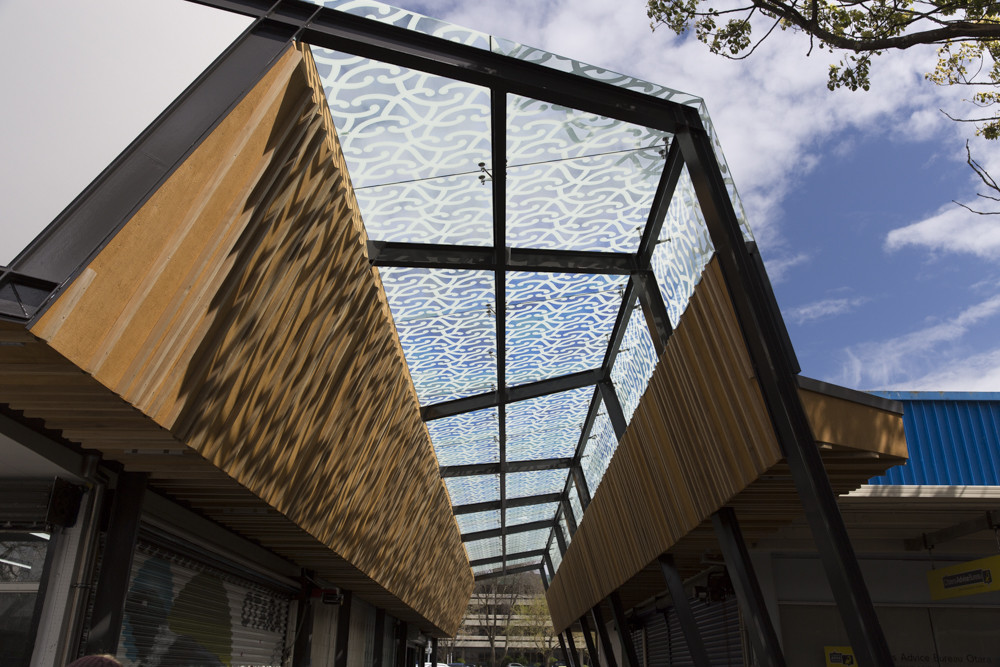

This makes SafeLite™ STF Sentry ideal for special applications such as balustrades, structural glass walls, fins, canopies, glass floors, any fixed point glazing application, and some security applications.

These structural laminates are so strong and stiff they can hold a toughened laminated panel together even if both panes are fractured, reducing the likelihood of injury to nearby persons from broken glass fragments. In some cases they can be bonded to metal so special stainless steel fittings can be bonded into the glass, via holes and notches.

In addition to its strength, SafeLite™ STF Sentry retains its clarity – even after years of service and is much less vulnerable to moisture exposure or yellowing over time.

Safelite™ STF Sentry is manufactured to order by Metro Performance Glass and can be customised to suit specific project requirements.

SafeLite™ STF Sentry benefits

SafeLite™ STF Sentry is a Grade A safety glass.

Can be manufactured with annealed, heat-strengthened or toughened glass plies, to suit the specific needs of the installation.

Retains some load bearing capacity even when both panes of glass are broken:

Allows for a fully frameless glass balustrade, without the need for an interlinking rail or stiffener brackets (subject to minimum panel width requirements).

Offers increased intruder resistance (compared to annealed PVB laminate).

Less likely to fall out of overhead point fixed applications (canopies).

SafeLite™ STF Sentry offers improved sound reduction (compared to single/monolithic glass).

Reduces UV transmission by approximately 99%.

As SafeLite™ STF Sentry is manufactured to the project specific specification, a wide range of finishes can be incorporated, including tints, translucent or coloured interlayers, and digitally printed images.

TempaSoak™ (heat soak tested safety glass)

Heat soaking is a secondary heat treatment process which substantially reduces the likelihood of toughened safety glass breaking spontaneously after installation.

This secondary process (completed after the thermal toughening of the glass), reduces the chance of spontaneous breakage from 1 in 10,000m2 to 1 in 1,000,000m2 (Glass and Glazing Federation UK).

TempaSoak™ (heat soak tested safety glass) is recommended for any toughened safety glass (including toughened laminated safety glass) that is in a critical location for safety, or would be difficult to replace (eg glass floors, high -rise structural glazing).

Please note: soft coat Low-E glass is generally not suitable for heat soak testing – contact your local Metro Representative if this is being considered.

Background

During float glass manufacture, impurities in the glass batch can result in inclusions in the finished product. These inclusions are so small that they are normally invisible to the naked eye and may not all be detected by the float glass production scanners. The most well known of these inclusions is nickel sulphide (NiS) crystals/stones, which can be contained in the raw material during the production float glass.

The glass toughening process requires the glass to be heated to just below its softening point and then rapidly cooled. Because this heating and rapid cooling process induces substantial tension in the glass (increasing its strength), inclusions in the tension core can cause spontaneous breakage, as they are known to change phase and expand some time after the toughening process.

Heat soak testing is a reliable way to reduce the likelihood of undetected inclusions causing spontaneous breakage of toughened safety glass.